Breaking trail

Pagosa wool apparel company thinks outside the big box

by Page Buono

|

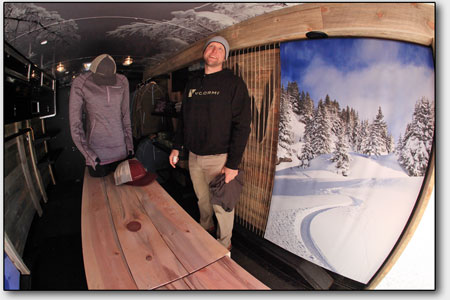

| Timm Smith, marketing director at Voormi, shows off the inside of the company’s retro-fitted snowmobile trailer/mobile display room at Pagosa headquarters on Monday. The company uses Colorado sourced merino wool for its “small-batch” wool apparel./Photo by Steve Eginoire |

Hailing from some obscure corner of Greek mythology, the Voormi thrived in a world of ice and snow. The furry, three-toed creatures survived inclement weather by adapting to local conditions and creatively utilizing resources. For snow and ice dwellers in the modern world, Voormi, (pronounced “voor-mee”) is a business that does the adapting for its clients.

This up-and-coming Pagosa clothing manufacturer is taking wool products for backcountry living to the next level. Using merino sourced from the Rocky Mountains of Colorado, the family endeavor strives to push the bounds of wool’s capabilities in the harshest of climates.

Dan English, founder and CEO of Voormi, came from a background in the software industry in the Pacific Northwest. In that world, things happen very fast, and the high-paced mentality is one of the pieces that drove him to reconsider his approach to the traditional mass-produced production model. “We don’t want to play the way the rest of the industry plays, we want to do it faster and that has to happen in small batches,” he said.

English compiled a strategic team of industry experts and people who live the outdoor lifestyle, including his children, Dustin and Megan English. An accomplished mountaineer, Dustin has guided everything from scientists in Antarctica to climbers on Denali and is currently a ski guide for the Alaska Mountaineering School (AMS). Megan is a patroller at Wolf Creek and aside from marketing, offers a platform for testing products nearby. Both Dustin and Megan were raised in Boulder, but had drifted down to Pagosa by the time the company was started, about four years ago.

The team was rounded out with Timm Smith, director of marketing, who hails from a background in the outdoor industry, his latest stint with Gore-Tex; and Mike Kissell, marketing associate, a snowboarder and “key guy” at events.

“It’s like working with family. It’s a hybrid of a casual environment that makes you want to be there, with the professional ability to get things done,” Kissell said.

|

| Smith holds a sample of raw Voormi wool. The company’s “precision blend” involves spinning the wool and synthetic yarns separately so the synthetic is on the outside and the wool is on the inside where it delivers the most benefits to the wearer./Photo by Steve Eginoire |

All together, there are five full-time employees and another five who work with the team on a contract basis. The company sources among friends and networks for things like photography and design, supporting local artists in the process.

“We’re a cast of characters that each come from a different angle, and we all wear multiple hats,” Smith said.

In some ways, Smith said Voormi is a “micro-brewery” of apparel, carefully crafting the product in small batches. “If you look at how the outdoor industry was founded, it was started by people who wanted to be outside and make better gear to do so,” Smith said.

Over the years, however, as the outdoor apparel industry grew, it went from authentic homespun endeavors to large businesses run by folks in board rooms. The competitive, mass-produced business model took over, driving people to supply chains. And suddenly, everything started looking the same.

“The local flavor is gone, and everything becomes super homogenous,” Smith said.

With this in mind, Voormi began as a blank state. The company asked a lot of questions about how things were made, why, what was needed in the field, and how it could be accomplished.

“The philosophy of not being constrained by the industry coupled with technology and what the team was doing with wool got me really excited to be a part of the team,” said Smith, who has been with Voormi for a little more than a year.

Because of the large-batch mentality focused only on the bottom line, the traditional industry is already focused on fall 2015. Smith said looking that far ahead creates a disconnect between what’s needed today and what is available, and leaves little or no room to correct faults later identified by consumers.

Instead, Voormi’s small-batch approach allows for quick tweaks, and stateside production creates a more direct connection between the products available and the consumer who needs it.

For example, Megan recently tested out a base layer on the job at Wolf Creek. She worked in the Voormi wool top for a week straight and – while fabulously stench resistant – the piece stretched out.

She took her feedback to the table, and they called in their fabric guru. After a few tweaks here and there, she was trying out the next layer just four weeks later, and the problem was solved.

To get it done right, Smith said each product is about 2.5 years in development. But, because the company makes its own fabric, early stages of the process are focused on the time-consuming art of developing fabric platforms, or prototypes, and once those are refined, each article takes less time.4

The evidence of the development process hangs as wool and fabric swatches throughout Voormi’s comfortable “rugged-refined” office space on the east side of Pagosa. The wool is soft, and the dyes mimic the natural colors of the surrounding environment.

Thus far, the Voormi team has developed two different protoypes using wool sourced from the Rocky Mountains, a trait Smith said brings special characteristics as the sheep were raised in the region Voormi is targeting. The wool, after being combed and spun and knitted – all in the United States – is ready for the precision blending process Voormi prides itself on developing.

Traditionally, blends are created by weaving multiple fibers together into what Smith refers to as a “cocktail” yarn. But, in doing so, wool often loses some of its best attributes. When nylon or polyester, for example, are incorporated to create a more abrasion-resistant outer edge, it lessens the benefits of wool next to the skin.

So, Voormi does what it calls “precision blending,” where the pure wool and high-performance synthetic yarns are not spun together but rather spun separately into individual yarns and then knit into unique patterns that push the synthetic to the outside and the wool closer to the skin.

For now, Voormi is selling its limited edition High-E hoodie online. The mid-layer hoodie is its first product, but a “built up” version of that jacket, the Drift Jacket, as well as a lighter, slimmer version called the Access will soon be available. Base layers and pants are also in the works.

While most of its products are wool, the team found itself wanting basics like T-shirts and hoodies. So, it developed a line of everyday wear and other Voormi “shwag,” all of which is also U.S. made.

While most of its products are wool, the team found itself wanting basics like T-shirts and hoodies. So, it developed a line of everyday wear and other Voormi “shwag,” all of which is also U.S. made.

When it comes to sales, Smith said, “like everything else, we try and be different.”

Voormi products are available online and at various retailers in Pagosa, including their headquarters. However, Smith said, they try to refer clients to local retailers to increase sales there.

Voormi’s retro-fitted snowmobile trailer also does double duty as a marketing venue. Clean and artfully designed, the trailer converts easily from sled trailer to showroom, depending on the occasion. For the upcoming SnowSports Industries America (SIA) snow show in Denver, the trailer will serve as the team’s booth as well as host to an all-important corn-hole tournament.

“It’s great to be genuine about what you’re selling,” Kissell said, looking forward to the upcoming trip.

As the company looks to the future, it plans to maintain Southwest Colorado as Voormi’s epicenter and expand in concentric circles from there.

“Fast-forwarding 10 years and looking back, we would be really proud if we were seen as the company that pushed the envelope on the capabilities of wool. We want to take it from socks and underwear to skin-to-shell performance backcountry. We want to map product evolution that allows somebody in 10 years to not have to have a hodge-podge of synthetic layers, but instead wear a full wool kit,” Smith said, adding that maintaining the small batch mentality and strong retailer relationships are crucial.

Back to the concept of a blank canvass, Smith said the only way to stay authentic is to break new ground. The minute you look to others, he said, you’re in the same game as everyone else.

“In a way, we’re back to shovels and axes, on the road right next to the super highway,” Smith said. “Otherwise, you’d never get new roads, just more crowded highways.”

There is currently no content available.

In this week's issue...

- May 15, 2025

- End of the trail

Despite tariff pause, Colorado bike company can’t hang on through supply chain chaos

- May 8, 2025

- Shared pain

Dismal trend highlights need to cut usage in Upper Basin, too

- April 24, 2025

- A tale of two bills

Nuclear gets all the hype, but optimizing infrastructure will have bigger impact