|

Smaller is better for 'microbrew

of snowboards'

by Missy Votel

|

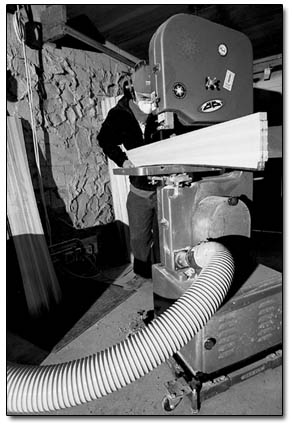

| Venture Snowboard’s

Klemens Branner makes a cut on a core for one of his

boards in his Bayfield shop on Monday. The procedure,

called “bookmatching,” ensures symmetry

(below) and lends Venture boards their unique look.

The wood is certified by Smart Wood, a program of

the Rainforest Alliance that certifies wood as sustainably

harvested./ Photos by Ben Eng. |

Klemens Branner has always been inventive.

Intrigued by a snowboarding scene in a James Bond movie

in 1986, the financially strapped 15-year-old fashioned

his own board using his father’s tools and a piece

of plywood.

“I spray-painted the bottom pink because it was

the only paint we had and put some junkie rubber straps

on to keep my feet in,” he said.

Despite its crude design, the contraption was an instant

hit among the kids at a park in Denmark, where he grew

up. And Klemens, for one, was instantly smitten.

“It was a little rough, but we had a good time,”

he said.

Today, the love affair with the sport has taken Klemens

from that small Scandinavian sledding hill to the base

of the San Juan Mountains. And although much has changed

since those early plywood-and-spray-paint days, “Klem,”

as his friends call him, is still turning out handcrafted

boards, albeit with a higher level of sophistication.

“We

joke around and call ourselves the microbrew of snowboards,”

said Klem’s wife, Lisa, who is the management and

marketing end of Venture Snowboards, the couple’s

Bayfield-based company. The couple moved from Fort Collins

about a year ago in search of a simpler, less hectic lifestyle. “We

joke around and call ourselves the microbrew of snowboards,”

said Klem’s wife, Lisa, who is the management and

marketing end of Venture Snowboards, the couple’s

Bayfield-based company. The couple moved from Fort Collins

about a year ago in search of a simpler, less hectic lifestyle.

“We were fed up with the city and the Front Range,”

said Lisa.

As big fans of Wolf Creek, they had become familiar with

the San Juans and decided rural La Plata County suited

their needs. Indeed, the rustic setting of the couple’s

home and workshop – nestled along a rutted dirt

road in a small canyon north of town –seems an ideal

setting for the company, which eschews the ideals of mass

production in favor of small batches of boards, created

with an eye toward simplicity and sustainability.

“We like to cater to the older riders, people who

aren’t going to buy because of its graphics,”

said Klem, who at 32 has been riding for more than half

his life.

In fact, the current line of Venture boards (there are

three models that come in varying widths) come in only

a few solid colors: red, green, blue, black and orange.

“I think they look like Jolly Ranchers,”

said Lisa, whose production duties include cutting the

Venture logo into each base.

To borrow a cliche, they care mostly about what’s

on the inside: a laboriously handhewn wood core. Klem,

who worked several years for a snowboard manufacturer

near Denver before branching out on his own, cuts each

core himself, using a woodworking technique called “bookmatching,”

which ensures symmetry. Stacking two different kinds of

wood (ash for the edges, softer poplar in the middle for

flex), he cuts each block lengthwise, producing a carbon

copy of itself. The two identical pieces are then placed

side by side, making up the core.

Klem, who holds a master’s degree in mechanical

engineering, is happy to offer up a lengthy explanation

for the technique – not to mention the entire snowboard-making

process. But in the end, he says it just makes for a better

ride.

“It corrects for wood’s natural variations,

so your board responds the same on both its right and

left edges,” he said.

Sure, some (including his wife) may accuse Klem –

whose workshop floor is clean enough to eat off of –

of a slight proliclivity toward being anal. He prefers

to think of it as attention to detail – a “do-it-right-the-first-time”

mentality.

“You end up with a much better product,”

he said. “In the end, I think it’s worth it.”

|

| Lisa Branner pops plastic

letters for the logo into the base of a board. The

process not only creates a twotoned logo but cuts

down on waste, she said./Photo by Ben Eng. |

The process also makes for an interesting visual –

which in a roundabout way has become Venture’s trademark.

In an effort to cut down on the amount of plastic used

in its boards, Venture uses epoxy-soaked fabric as the

protective covering, or top sheet, of the board. The result

is a translucent effect, which allows the core to show

through and gives the boards an old school look more reminiscent

of fine cabinetry than a piece of outdoor equipment meant

to be used and abused.

At first, the Branners were unsure if the approach would

fly.

“We wondered, ‘Do people really want to see

the core?’” said Lisa. “But then we

figured, we put so much time and effort into it –

that should be what people see.”

So far, the approach seems to be working, with all of

last year’s stock of boards selling out by Christmas.

In fact, Venture has even caught the eye of a Hollywood

celebrity – Seal – who called last week to

have a board overnighted. He called back the next day

to order three more.

“He said he had to have one for a friend, and a

powder board and an all-mountain board,” said Klem.

Despite the brush with stardom, Klem and Lisa remain

very much rooted in their grassroots, low-key approach.

For the most part, their marketing consists of word of

mouth, relying on a handful of dedicated riders throughout

the West to talk up their boards. And rather than paying

for a team of sponsored riders, they have amassed a small

group of homegrown local riders.

“None of these people get paid to ride for us,”

said Klem. “They just do it because they live to

ride.”

Venture also takes a low-impact approach to production,

which involves the use of sustainably harvested wood and

organic fabric top sheets (yes, there’s even a hemp

model).

For the Banners, the decision to run a green company

was a given.

“Obviously, the connection is, we love to be outdoors,”

said Lisa. “Here’s a piece of equipment that

we’re going to be using outdoors, it just makes

sense to be sensitive to wanting to preserve that.”

|

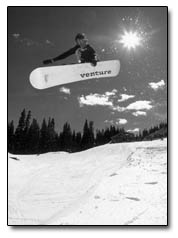

Erik Mishker, a rider

for Venture’s

grassroots local team, conducts a

little R&D at DMR’s terrain park

last year./Photo by Ben Eng. |

And as the first snow of the season fell outside their

workshop window, the Branners were cautiously optimistic

heading into another season. Since beginning five years

ago, they have doubled production each year and have now

landed a spot on the shelves of Bubba’s Boards,

which will also carry their demo boards. And with the

addition of a press for laminating the boards this summer,

which Klem made from the ground up and considers to be

his trade secret and “pride and joy,” Venture

now has more flexibility in its production.

“We’ll see what kind of demand we have,”

said Lisa. “We have the capabilities to build midseason.”

Of course, with each board taking more than four hours

to produce, this could cut into their riding time. But

next to being knee-deep in powder, there’s only

one other place Klem would rather be: in his workshop,

with Zappa blaring (the only place in the house where

he’s allowed) and the power tools buzzing.

“When I’m covered in sawdust and my hands

are all glued up – that’s when I’m the

happiest.”

|